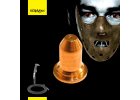

Plasma

A plasma cutter is a tool that uses extremely high temperatures to cut conductive materials such as steel, aluminium or copper. An electric arc is created in the cutter that ionizes a gas (usually compressed air or another inert gas-thus the need for a powerful compressor). The ionized gas becomes plasma-a hot, conductive state of matter. The plasma generates intense light and heat, reaching temperatures of up to 30 000 °C. This is much higher than the melting point of metals. When the plasma flows onto the material being cut, it melts the metal at the point of the cut. The high pressure of the plasma and gas removes the molten metal, creating a narrow and precise cut.

Product sorting

List of products

In order to be spliced it must first be cut. Don't let your creativity limit you when cutting metal accurately. One machine, incredible possibilities. Faster work and better...

In order to be spliced it must first be cut. Don't let your creativity limit you when cutting metal accurately. One machine, incredible possibilities. Faster work and better...

In order to be spliced it must first be cut. Don't let your creativity limit you when cutting metal accurately. One machine, incredible possibilities. Faster work and better...

Listing controls

Advantages of plasma cutting:

- Speed: The plasma cutter is very fast and efficient. Accuracy :

- The cuts are usually very precise and clean. Versatility:

- A wide range of materials and thicknesses

- can be cut

- . Relative simplicity:

- The plasma cutter is relatively easy

- to operate

- .

Usage:

Plasma cutters are used in many industries such as:

- Metal fabrication:

- Cutting profiles, sheets and other metal elements. Demolition :

- Cutting large metal structures.

- Automotive:

- Cutting of car bodies and other metal parts. Shipping

- industry:

- Cutting steel plates for shipbuilding.

_en.png?678531f8)